Synchronized mechanization, sugar cane yield doubled

According to Mr. Nguyen Hoang Phuoc, Deputy Director of An Khe Sugar Factory (Gia Lai – a unit of Quang Ngai Sugar Joint Stock Company): Realizing that the sugar cane yield in the raw material section is only more than 50 tons/ha on average, Too low in Compared to the potential, Quang Ngai Sugar Joint Stock Company instructed An Khe Sugar Factory to plan synchronous production mechanization to improve sugar cane productivity in the raw material sector. Since 2012, An Khe Sugar Factory has been mechanizing sugar cane production from planting to harvesting in Dong Gia Lai districts: Kbang, Dakpo, Kongchro and An Khe Town.

Mechanization of the sugar cane harvest. Photo: VDT

Mr. Phuoc reminded that in the 2011-2012 sugar cane harvest year, because it was so new, farmers did not respond to mechanization, so Dong Gia Lai sugar cane area was only more than 2,118 ha of farmers mechanized of soil preparation, planting, tending and fertilization. After the application of mechanization in the above stages, sugar cane productivity increased significantly, in the 2013-2014 crop year, the sugar cane area invested in mechanization increased to more than 5,359 ha. Sugar cane farmers in particular saw the benefits of mechanized cultivation and boldly changed their traditional farming methods, whereby the area of mechanical sugar cane cultivation increased from year to year.

“Currently, large fields with synchronous mechanization are yielding about 100 tons/ha on average, more than the previous average yield of 50 tons/ha; In particular, there are areas with a productivity of up to 120 t/ha. The mechanized areas have not synchronized with the average yield of almost 74 tons/ha, almost 24 tons/ha higher than the previous average yield,” said Mr. Nguyen Hoang Phuoc.

According to Mr. Tran Quang Kien, director of An Khe Sugar Factory, the mechanization of sugar cane production has brought significant economic benefits to sugar cane farmers in the region. Thanks to the application of mechanization to production, the Dong Gia Lai Sugarcane Raw Material Area has basically provided enough raw materials to operate the An Khe Sugar Factory. If the mechanization of sugar cane cultivation is replicated and heavily invested by farmers, the expansion of the eastern Gia Lai raw material area to 30,000 ha is within reach of the An Khe Sugar Factory.

Mechanization of sugar cane cultivation. Photo: VDT

Dak Hle Township, a remote place in Kbang (Gia Lai) District, where the natural area is only 1,995 ha but the sugar cane area occupies 1,400 ha, evenly divided into 3 villages and 1 village. Previously, sugar cane cultivation in Dak Hlo was done manually.

According to Mr. Bui Phich, Chairman of the People’s Committee of Dak Hle Municipality, more than 10 years ago, when cultivating sugar cane, the fields were still only “buffalo goes first, plow follows”. However, after a number of local sugarcane farmers invested in tillage mechanization, Dak Hle sugarcane farmers found that tillage became easier, costs decreased and productivity increased significantly, so they gradually followed suit. To date, 100% of the sugarcane acreage in Dak Hlo has been mechanized from tillage to planting, fertilizing and harvesting.

“Since the synchronous mechanization of production, the sugar cane yield at Dak Hle has increased from less than 50 tons/ha to an average of 70 tons/ha, an increase of more than 20 tons/ha. Besides the machinery and equipment of An Khe Sugar Factory, many private households here also invest in purchasing sugar cane planting machines, manure spreaders, tillers, tractors, harrows and tractors to serve the local sugar cane farmers.

Mechanization in production has helped sugar cane farmers in the East Gia Lai region face fewer and fewer difficulties, and profits are increasing. Photo: VDT

The high sugar cane yield in Dak Hle is also due to the farmers following the fertilizer application process to replenish the soil and thanks to the new sugar cane varieties introduced by the An Khe Sugar Factory. Sugarcane varieties like KK3 and Uthong have high yield and sugar, so farmers benefit greatly,” said Mr. Bui Phich, chairman of the Dak Hlo Municipality People’s Committee.

“Thanks to synchronous mechanization, sugar cane in Dong Gia Lai raw material area has achieved higher productivity and quality than before; plus savings in labor and production costs, so the farmers are quite profitable. Despite facing stiff competition, the factory has since gained a competitive advantage in the market thanks to the reduction in product costs through the application of mechanization. From this advantage, An Khe Sugar Factory invests about VND 350 billion every year to invest in mechanization and development of raw material areas in Dak Po District, Kongchro District, Kbang District and An Khe City without interest.” Mr. Tran Quang Kien, Director of Said a Khe sugar factory.

“Health Check” to replenish the land

According to Mr. Nguyen Hoang Phuoc, deputy director of An Khe Sugar Factory, the sugar cane yield in Dong Gia Lai raw material area increased from 24 to 50 tons/ha compared to 10 years ago by contributing to “health promotion” for the country. The “health supplement” for the soil is carried out through the study of soil nutrition and the recommendations for rational use of fertilizers jointly applied by Quang Ngai Sugar Joint Stock Company and Viet Nhat Fertilizer Company.

Employees of the Viet Nhat Fertilizer Company take soil samples in the Dong Gia Lai area for analysis. Photo: NMD.

After 4 years of strategic cooperation to develop sugar cane fields in Dong Gia Lai area, Viet Nhat Fertilizer Company submitted a map of current soil nutrient status to Sugar Joint Stock Company, Quang Ngai at the end of 2020. Based on this nutrient status map, An Khe Sugar Factory has developed a suitable cultivation and fertilization method for each soil type, which helps sugar cane farmers to improve production efficiency.

According to Mr. Nguyen Hoang Phuoc, An Khe Sugar Factory has received 15 maps from Viet Nhat Fertilizer Company, including 3 maps on sampling, soil classification, land use status and 12 physical maps on current soil nutrient status in districts and cities with an assessed area over 29,463ha .

“In order to map the current status of soil nutrients, Viet Nhat Fertilizer Company has taken 226 soil samples since 2011, of which 205 samples have recorded full coordinates and analysis results using the kriging interpolation method. Viet Nhat Fertilizer Company prepares a brief report on sampling, analysis and mapping methods of soil nutrient status in commodities area and recommends sugarcane farmers to apply appropriate fertilizers for each soil type, avoid waste and increase efficiency,” Mr. Phuoc said.

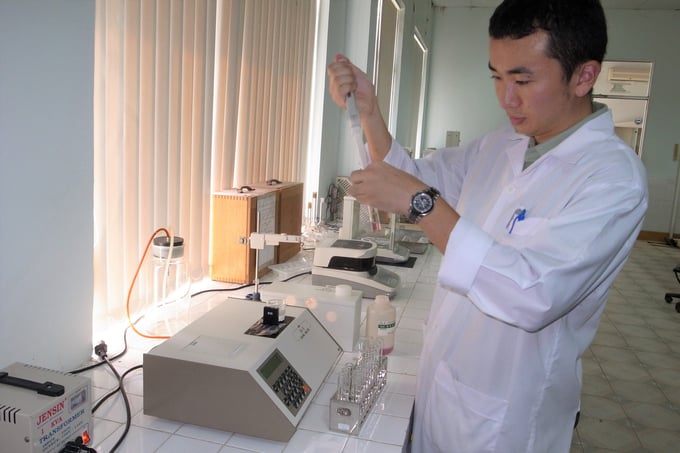

An employee of the Viet Nhat Fertilizer Company analyzes soil samples. Photo: NMD.

In fact, by applying the current map of soil nutrients to production, farmers can reduce input costs and increase profit per ton of sugar cane, making the application of 4.0 technology more convenient in production. Based on this nutrient map, An Khe Sugar Factory recommends farmers to use appropriate fertilizers for each soil type to increase production efficiency.

“The nutritional status map shows which substance is lacking in which soil, so that farmers can add them in the cultivation process. The dose of fertilizer used is appropriate, neither for excess nor for deficiency, but only fully covers the needs of the plants. The above solution helps farmers save the cost of fertilizing sugar cane, which is very beneficial, especially in the context of fertilizer price increases like today,” said Mr. Nguyen Hoang Phuoc, deputy director of An Khe Sugar Factory.

“The soil in the Dong Gia Lai sugar cane area is mainly low pH and humus. For areas with a pH below 5.5 it is necessary to apply lime from 1,000 kg/ha/plant, areas with a slightly higher pH can apply lime from 500-800 kg/ha/plant.

Regarding humus, organic matter in soil plays an important role in storing and providing nutrients to sugar cane, helping to improve the physical, chemical and biological properties of soil, and is also an important factor. determines the fertility of the soil. Therefore, in areas with little humus, we instruct farmers to apply factory-provided organic fertilizer or sewage sludge,” added Mr. Nguyen Hoang Phuoc.