[ad_1]

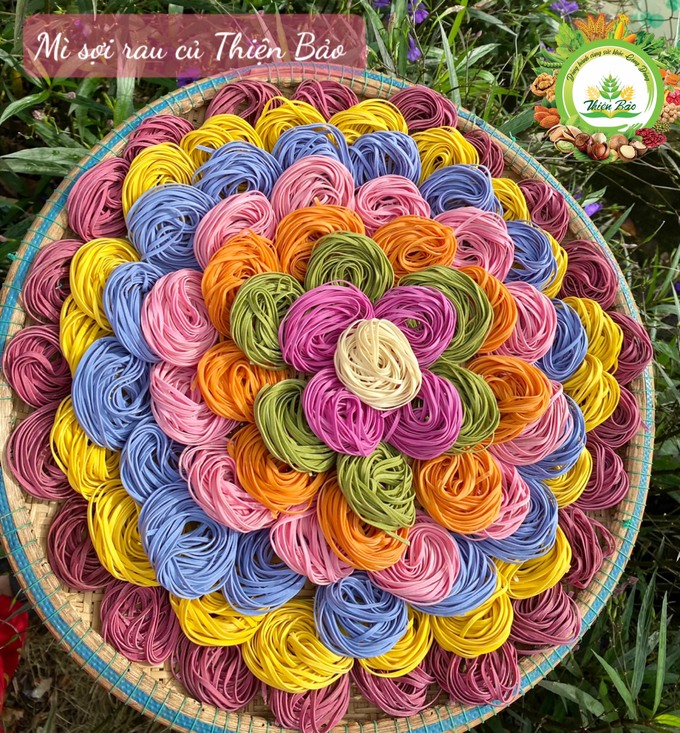

QUANG TRI Since the source of the dyes is locally grown vegetables and tubers, the Thien Bao facility has produced colorful noodle products that are fascinating to look at.

In the warm sun of the first day of March, we had the opportunity to visit Thien Bao Nutritional Food Production Facility, a start-up business development model by Ms. Le Thi Phuong, located in Dong Van Village, Trieu Son Township, Trieu Phong District (Quang Tri ).

Colorful noodles are a very eye-catching feature of the Thien Bao establishment. Picture: Viet Toan.

Ms. Phuong said that from 2017, she started developing the production and business of food products made from safe local sources of agricultural raw materials, such as grain powder, Mind Tea, etc. Noodles with the addition of vegetables and fruits to make a difference and attract consumers .

The raw material source for the vegetable noodles are local organic farm products, which are pre-processed, dried and extracted after harvesting. Currently, the Thien Bao facility offers noodles of many different colors, such as: yellow of turmeric and gourd; green of spinach; beetroot brown; orange from gac and carrot; purple from purple sweet potatoes; pink from the red dragon fruit; blue from the butterfly pea flower; white from lotus seeds; black from black sesame…

Ms. Phuong’s facility has created jobs for many local workers. Picture: Viet Toan.

Ms. Phuong said that the essence of vegetables, roots and fruits are mixed with the noodles and kept at a low temperature to increase the noodles’ toughness. The annealing, rolling and subsequent cutting phases are carried out according to a methodical process with strict specifications. In particular, products from Thien Bao Nutritional Food Manufacturing Facility do not use preservatives and additives, and strictly comply with government regulations on food hygiene and safety.

“The vegetable content in noodles is 30-40%, which is very suitable for the needs of consumers in each meal. After the noodles have been processed into fibers, they are rolled, this step requires the skill and experience of the noodle maker, as it is necessary to create a suitable gap to avoid friction, support the shape and prevent the noodles from sticking together. After that, it is transferred to the cold drying stage for about 18 hours to squeeze out all the water and extend the storage time. This stage is crucial for the quality of the noodles,” said Phuong happily.

Thien Bao’s noodle products use no preservatives or additives. Picture: Viet Toan.

On average, Ms. Phuong’s facility puts 18-20 tons of flour and vegetables on the market every year, bringing in revenue of VND1-1.2 billion, of which profit accounts for 20%. The facility creates regular jobs for 5 employees with an income of 4-5 million VND/person/month and many seasonal workers in the area.

The economic development in rural areas with the model of vegetable noodles has created fresh colors from nature for traditional noodles. With dynamism and innovation, Thien Bao vegetable noodles in addition to economic development, creating jobs for many female workers, the model also helps many local women to use the family’s land, promote the cultivation of clean agricultural products, increase the connection with production facilities Income.

Thanks to the production of noodles, it has utilized and promoted the production of local vegetable and fruit raw materials, creating more income for the people. Picture: Viet Toan.

Ms. Le Thi Lien, an employee of Thien Bao Nutrition’s food production plant, said, “I have been working here for 2 years. After my marriage my main job is farming. To find a more stable job to increase income locally, it is very difficult to support the family, while still having to take care of the family, it is difficult to work far away. Also thanks to the Thien Bao facility that creates jobs and the tuition from the facility’s owner, Phuong, I have a very stable source of income…”.

Ms. Phuong also said that if people want to know about the processing or products at Thien Bao Nutritional Food Production Facility, they can contact us at 0369.602.502. She is very willing to share her methods and experience in production and processing. At present, Thien Bao vegetable noodle products have barcodes and codes, and are for sale on some e-commerce platforms, such as Soppe, Lazada, and some other sales channels, such as Facebook, Tiktok, Zalo.

[ad_2]

Source link