Ask

Currently, longan production in Vietnam is quite developed. Along with domestic consumption, Vietnamese longan has been exported to markets like China, USA, Australia, Japan, Korea, EU….

In order to develop longan cultivation, in addition to consuming fresh longan, it is important to increase production and consume processed longan. Because longan processing helps to consume longan in the off-season and consume all kinds of level 2 and level 3 longan, which increases the value of longan when deep processing.

In the processing of longan, the processing of longan is most important, because longan has high value, used by many people, and used for many purposes, such as storing, for a long time.

Regarding the production process, when fresh longan is brought to the processing plant, it is peeled, the pulp is separated from the seeds, and then placed in trays to dry.

Longan production is currently mostly small-scale, using a simple dryer that requires manual peeling and separating the pulp. Specialized seed separator and label sleeve (professionals often call it a label vortex pen). The spinning time for a longan is also about 12-13 seconds for professional workers, an average of 15-20 seconds, for ordinary people about 20-30 seconds.

Since most of the longan production plants in the provinces are currently not mechanized (the stages of sorting, peeling, separating the pulp, drying, bagging…), the profits are not high, which makes this type of longan production not well developed . If the authorities actively intervene to help longan production facilities to bring science and technology into production, it will help the development of longan production facilities. This will help the longan growth industry to develop further.

Construction of a mechanized longan factory

The following is a proposal for the mechanized production of longan. The longan factory in this concept proposal will mechanize the two main stages of the longan production process, namely using a dehuller, separating the pulp and using an automatic conveyor dryer.

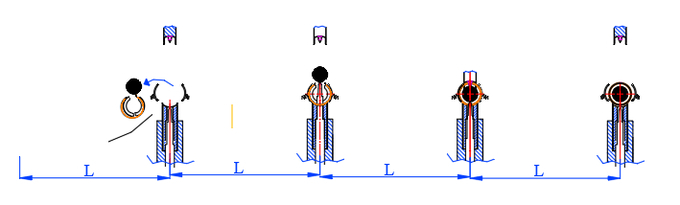

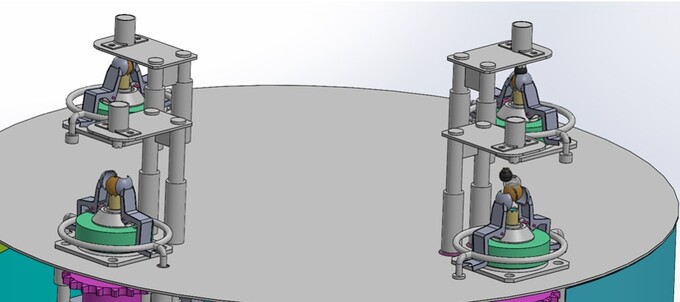

The idea of designing and making a peeler and peeling machine works in 4 steps as illustrated in the following images.

General working steps of the label peeling machine (order from right to left).

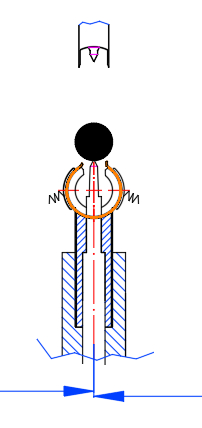

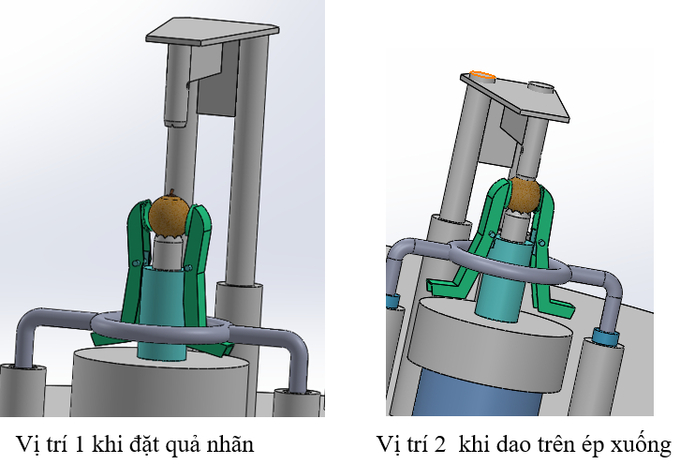

In position 1. (Step 1): The upper knife is raised, the pressing plate is open, the lower knife and the sowing lever are under the fruit. The worker places the fruit into the machine (requires the stem of the fruit to be rotated up and to the center of the knife position).

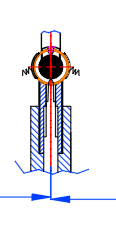

In position 2 (step 2): the upper knife lowers to cut through the rind and pulp to the core. The bottom knife is pushed down by the fruit, so it cuts the peel, it is necessary to push the seeds up, press on the seeds.

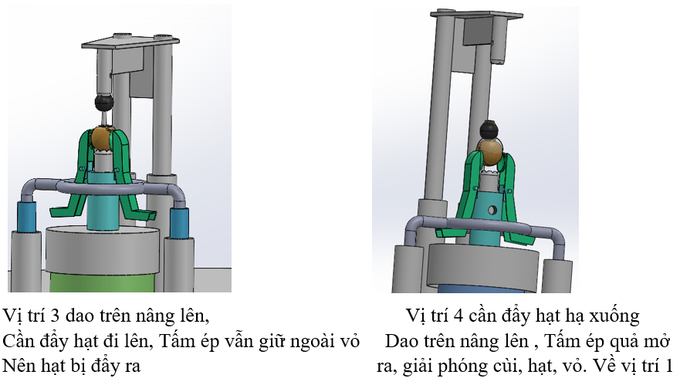

In position 3 (step 3): During the process from position 2 to position 3, the two press plates are rotated from ½ to 1 revolution around the axis of the seed pusher to break the husk. At position 3, the upper knife is raised and at the same time the lifting lever pushes the seeds out of the pulp. The press plate is still pressed to hold the skin and pulp.

In Position 4 (Step 4): The push rod falls off, the seed, peel and pulp are pushed out and the kit returns to Position 1.

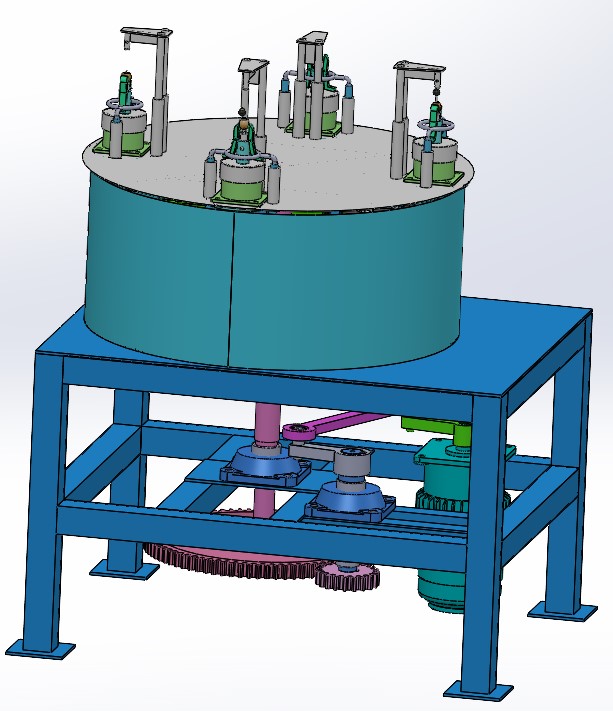

When this kit is placed on a circular disc, the disc will rotate 1 revolution through 4 positions. So the disc rotates 1 revolution, peeling and separating 1 fruit. If there are 4 sets on the plate, the machine separates 4 balls at 1 revolution. When the disc rotates at 60 rpm (1 rpm), the machine separates 4 sets on the plate 4 x 3600 = 14,400 fruits/85 fruits/kg = 169 kg of fresh longan. The problem is that the worker can put the balls into the machine in 1 second. If you can order 1 fruit/second, the yield is 3,600 fruits/hour, if you can put 2 fruits/second, the yield is 7,200 fruits/hour, if you put a lot, the machine productivity is high, and then you have around more Add work to collect seeds and husks from the mixture of husks, seeds and pulp.

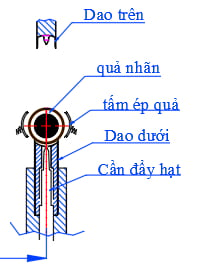

The steps of peeler and peeler machine.

Longan peeler and peeling machine.

4 steps on the vegetable peeler, remove the flesh of the longan.

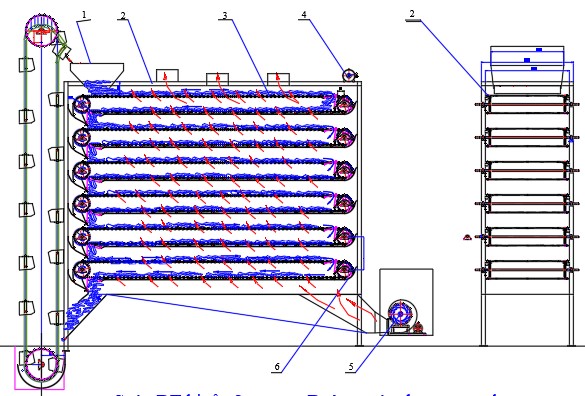

Using a continuous dryer, indirect drying to dry longan pulp

Diagram of a conveyor dryer used to dry longan.

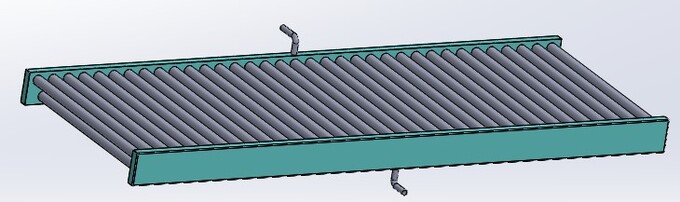

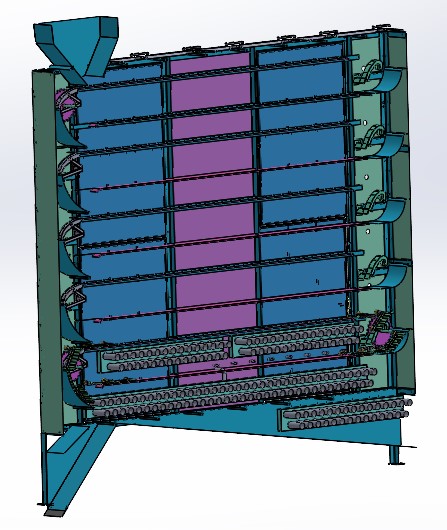

Drying chamber with perforated stainless steel sheet drying floor.

Seamless heat exchanger tubes.

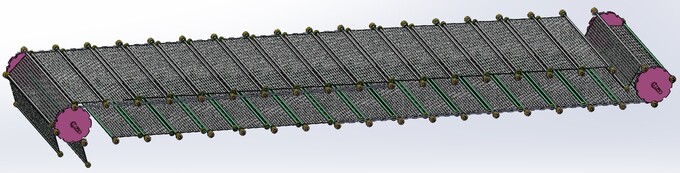

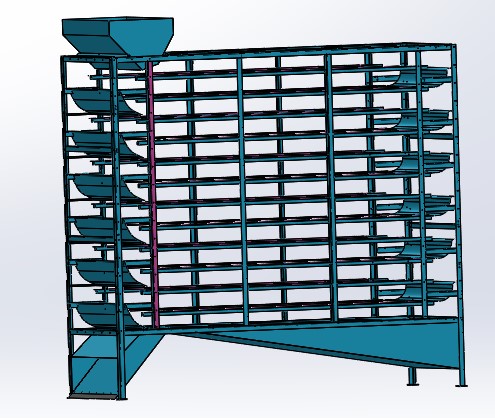

Frame of the dryer housing.

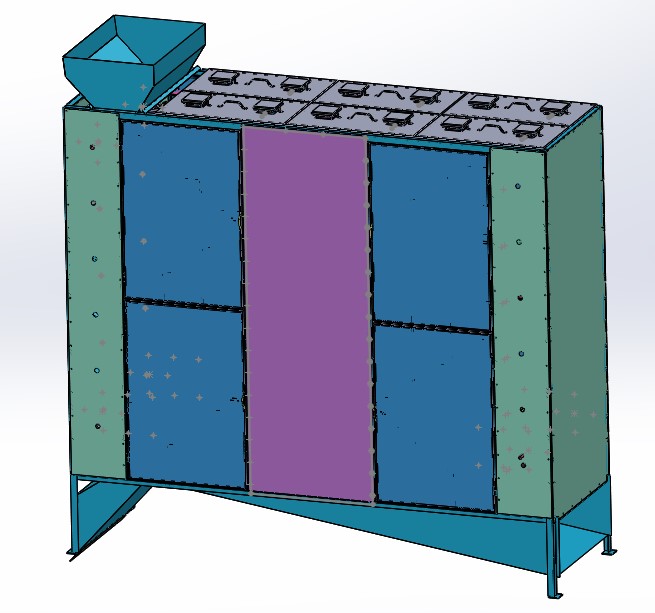

Total dryer.

Vertical section of belt dryer, automatic control

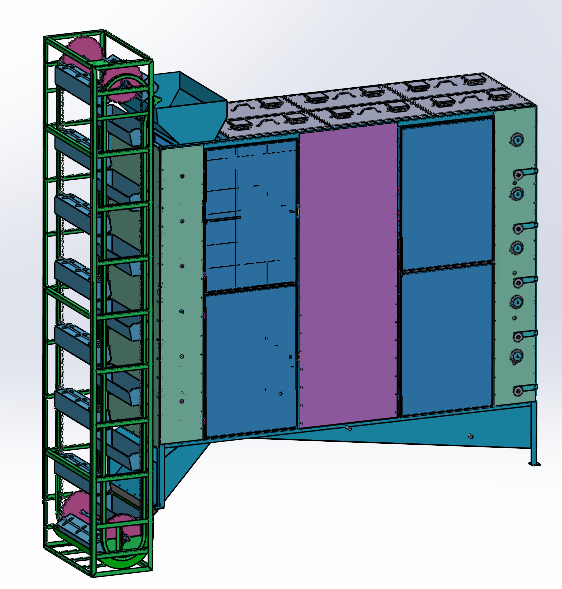

Total belt loading and dryer.

Automatic belt dryer. Fresh longan raw materials are loaded into the dryer by bucket. The drying heat is supplied via the boiler. The drying temperature is automatically adjusted according to the preset programming and adjusted according to the technological needs in order to obtain the best product. Longan is automatically mixed during the drying process. The estimated machine capacity is 120 kg finished products/day.

Calculating the economics of the longan production model using mechanization

Based on the parameters of the longan production and trade season in 2022, the following can be seen: the price of class 1 longan for export or import for class 1 supermarkets is 17-20,000 VND/kg. The price of longan type 2 and longan is 7-8 thousand VND/kg. Peeling and separating the flesh of longan costs VND 4,000/kg of fresh fruit. Longan price is 125 – 130,000 VND/kg. The average yield of peeled and separated longan is 40 kg of fresh longan/day. 10 kg of fresh longan yields about 1.2 kg of longan. The harvest time for the production of longan lasts 35 days/year.

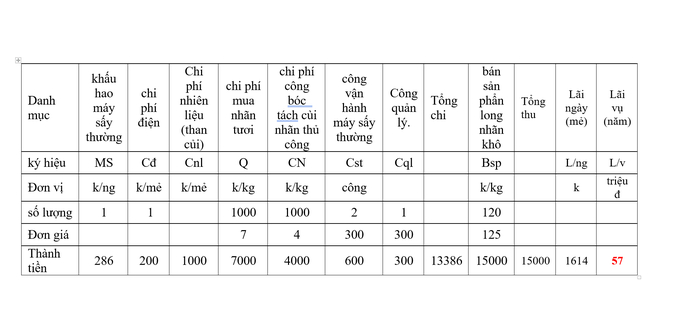

Table 1: Economic efficiency of a traditional longan producer.

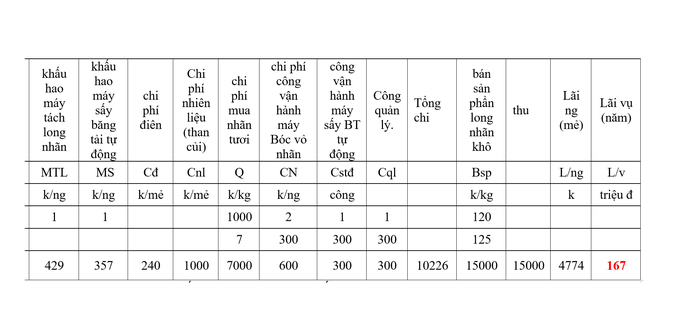

Table 2: Economic Efficiency of Mechanized Longan Production Model.

For a simple comparison with a production plant processing 1 ton of fresh longan/day to produce 120 kg of longan/day, see Tables 1 and 2, we see that the longan production mechanization model is proposed to be applied more than twice more profitable than traditional ones establishments. The applied model proposed here will bring benefits to longan processors, since then many households will be involved in longan processing, which will help the provincial longan industry to develop stably and increase the price of longan.